The Rising Demand for Industrial Robots in Manufacturing Global Market Growth Projections Global industrial robotics markets look set for impressive growth over the coming years. Industry forecasts point to a compound annual growth rate above 10% b...

VIEW MORE

How Welding and Cutting Robots Enhance Production Efficiency Automating High-Precision Tasks with Laser Welding Machines Laser welding equipment plays a big role in jobs that demand pinpoint accuracy throughout many different sectors like automotiv...

VIEW MORE

Transformative Applications of Robotic Arms in Logistics Automation Warehouse Automation and Inventory Control Material handling in warehouses is getting a major boost thanks to robotic arms, which make logistics run smoother by cutting down on inv...

VIEW MORE

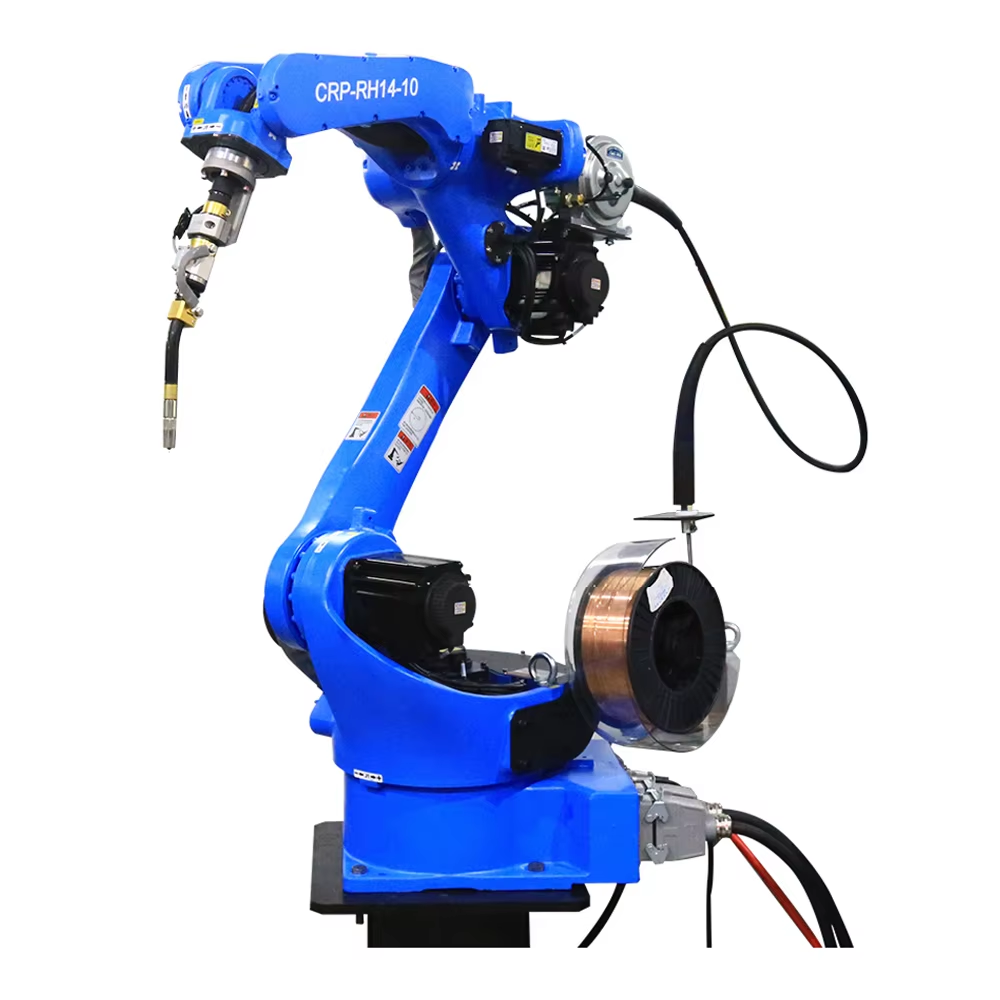

Core Components of Robotic Welding Systems A robotic welding system is made up of several key parts like the robotic arm itself, the actual welder, various sensors, and a central control unit. All these components work together to make welding proc...

VIEW MORE

The Rise of Collaborative Robots in Modern Industry Defining Collaborative Automation Collaborative automation is based on the creation of robots that can operate under the supervision of human workers, in order to maximise efficiency and worke...

VIEW MORE

Transforming Manufacturing with Collaborative Robots Laser Welding and Precision Assembly Applications Cobots, short for collaborative robots, are revolutionizing laser welding with 3 to 5 times higher processing speeds and 10 times more repeat...

VIEW MORE

How Laser and Plasma Cutting Technologies Work The Science Behind Laser Cutting Machines Laser cutting machines operate by directing a high-powered laser beam at a material, melting or vaporizing the material and making the perfect cut. This pr...

VIEW MORE

Defining Collaborative Robots and Welding Robots What is a Collaborative Robot (Cobot)? Collaborative robots The cobots are constructed in such a way as to operate safely alongside human workers, as well as to increase productivity and safety. ...

VIEW MORE

The Role of 6-Axis Robot Arms in Modern Manufacturing Advantages Over Traditional 3-Axis and 5-Axis Systems Six axis robotic arms bring some serious advantages when compared to older system setups, really transforming how manufacturing works on the...

VIEW MORE

Key Safety Standards for Collaborative Robot Arms ISO 10218 and RIA TS 15066 Compliance Requirements Keeping collaborative robot arms safe means following important standards like ISO 10218 and RIA TS 15066. These aren't just paperwork exercises bu...

VIEW MORE

Precision Engineering in 6-Axis Robot Arms for Spray Painting Multi-Directional Motion Control for Complex Geometries Six axis robot arms have changed how we approach spray painting because they can move in so many different directions at once. The...

VIEW MORE

Key Benefits of Automatic Welding Robots Enhanced Precision and Consistency Welding robots automatically perform their tasks with amazing accuracy thanks to sophisticated sensors and smart software that guide them through every weld according to st...

VIEW MORE