Key Benefits of Automatic Welding Robots

Enhanced Precision and Consistency

Welding robots automatically perform their tasks with amazing accuracy thanks to sophisticated sensors and smart software that guide them through every weld according to strict specs. When there's less variation between welds, the end products just look better overall. This matters a lot in places like airplane manufacturing and car factories where getting things right down to the millimeter makes all the difference. Some research indicates these machines can hit tolerances around plus or minus 0.1 mm, something most human welders simply cannot match consistently. Beyond meeting those tough industry standards, this kind of precision helps ensure that parts coming off assembly lines today are just as good as ones made yesterday or last week.

Increased Production Efficiency

Welding robots have a major edge over humans when it comes to non-stop operation. They just keep going without needing rest breaks, something no human worker can match. The result? Factories see a real jump in what they produce versus traditional manual welding methods. Some plants report boosting their Overall Equipment Effectiveness by around 20% after switching to robots. And let's not forget the speed factor either. Robotic welders typically work 2 to 3 times faster than their human counterparts, cutting down on how long each piece takes to make. This kind of speed means shorter wait times between products and more items rolling off the assembly line. For manufacturers dealing with strict deadlines, these time savings make all the difference in hitting production targets and keeping customers happy.

Improved Workplace Safety

Putting welding robots into action makes workplaces much safer because they cut down how often people have to deal with dangerous stuff during welding jobs. We're talking about really hot metal and all those bad fumes that hang around. According to what OSHA has been finding lately, factories that switch to robot welding see fewer accidents happening on site, which shows just how good these machines are at keeping workers safe. When robots handle all the boring repetitive welding work, humans get to do more interesting tasks instead. Workers aren't so tired anymore since they don't spend all day doing the same thing over and over again. Morale goes up when employees feel their skills matter, and this better attitude actually leads to getting more done while staying safe throughout the whole manufacturing process.

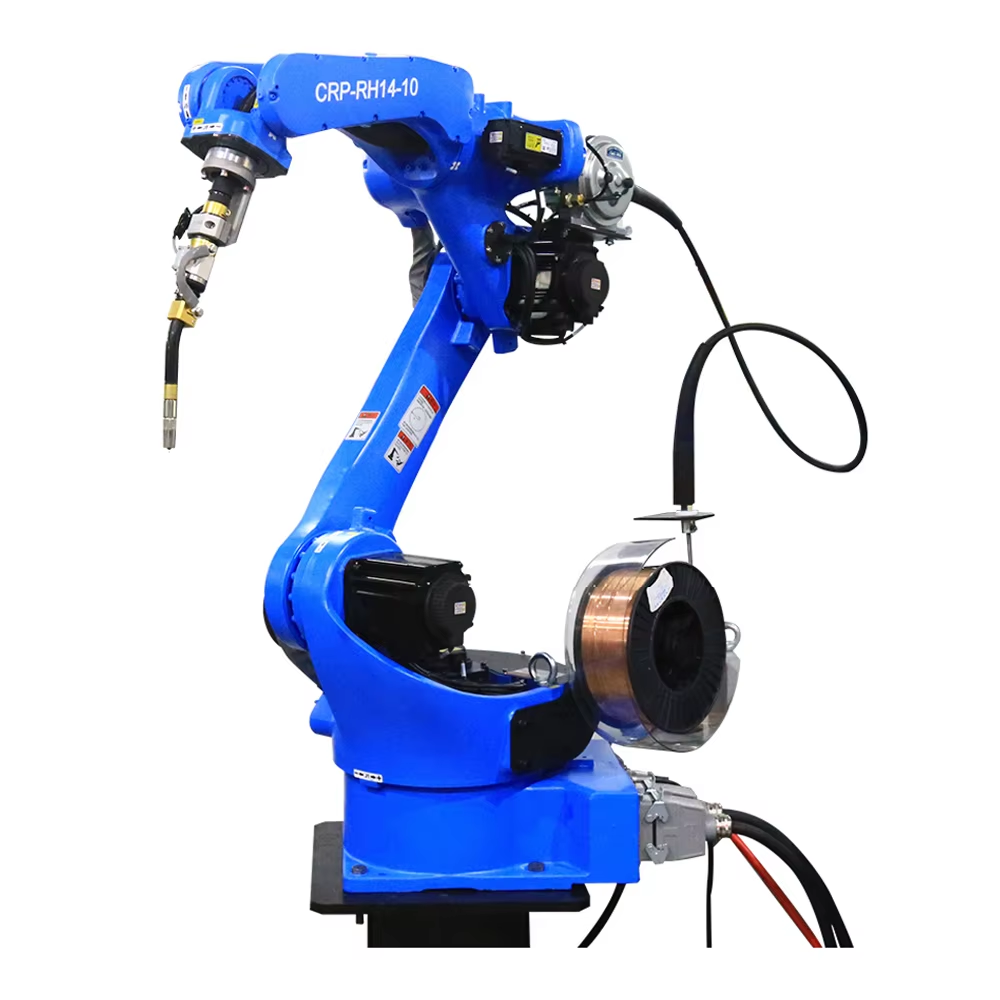

Main Types of Welding Robot Arms

Laser Welding Systems

Laser welding systems stand out because they can create really good welds with focused light beams, especially when working with thin materials found in things like smartphones and surgical instruments. What sets these machines apart is their incredible precision, letting engineers craft complex parts while still maintaining top-notch quality standards. Industry data shows that joints made with lasers tend to be much cleaner compared to traditional welding techniques, cutting down significantly on the time spent cleaning up after the fact. Because of this combination of accuracy and clean results, many manufacturers in fields where tiny details matter most have started switching to laser technology for their production needs.

Arc Welding Automation

Arc welding continues to be a dominant method in robotic welding because it joins materials through intense electrical arcs. Robotic systems for arc welding get programmed to handle complicated paths, which means they work well across different factory settings. When companies bring in automated arc welding, they often save money on labor costs something like 30% off what they used to spend. The machines also produce better quality welds faster than older techniques did back in the day. Factories that switch to this kind of automation typically see their output go up while running their production lines much smoother overall.

Collaborative Robotic Models

Cobots are these collaborative robots working right beside people on factory floors without those big safety cages we usually see around traditional machines. They really help streamline manufacturing because they can be programmed quickly and adapted for lots of different jobs. Factories that have brought in cobots report about a 30% jump in productivity numbers while also cutting down on worker strain from heavy lifting or awkward positions. When cobots take over boring repetitive work or those tough ergonomic tasks like reaching overhead repeatedly, workers get to concentrate on the more complicated parts of production. This creates a better balance between automation and human skills in modern manufacturing settings.

Industry-Specific Applications

Automotive Manufacturing

The auto industry has seen major changes since robotic welding came on board, mainly because it speeds things up and keeps quality steady across the board. Big car manufacturers say their factories run faster now that robots handle the welding jobs, and parts coming off the line are just as reliable week after week. The shift makes sense when looking at complicated car parts that need exact measurements. When companies switch to robot arms for welding tasks, they cut down on mistakes people might make during repetitive work, which means every weld looks pretty much the same from start to finish. Industry stats show cars makers buy more welding robots than anyone else in manufacturing, and this trend shows no sign of slowing down anytime soon.

Aerospace Engineering

Welding robots have become absolutely crucial in aerospace engineering when it comes to putting together those mission-critical parts that need to meet tough safety requirements. These machines have cut down on component defects quite a bit actually studies show around a 50% improvement in aircraft safety metrics. What makes robotic welding so valuable is how it achieves that sweet spot between strength and weight. The welds hold up under extreme conditions but don't add unnecessary bulk to aircraft designs. For manufacturers working on next generation aerospace systems, this kind of precision isn't just nice to have anymore it's becoming standard practice across the industry as companies strive to build safer, lighter aircraft without compromising structural reliability.

Heavy Equipment Production

Robotic welding plays a huge role in making heavy equipment, since manufacturers depend on these machines to construct durable machinery that can handle tough conditions. These robotic systems are really good at welding thick metals which is exactly what's needed for most heavy duty work. Some industry reports indicate that companies using robotic welding often see around 20-25% lower production costs, which explains why so many businesses are switching to this approach. When manufacturers bring robotic welding into their operations, they get better productivity while using resources more efficiently, which naturally cuts down on overall expenses in the long run.

Solving Modern Manufacturing Challenges

Combating Skilled Labor Shortages

The manufacturing sector is running into serious trouble finding enough skilled workers these days, so many plants are turning to automation as their way out. Research shows about 60 percent of manufacturers cant find qualified people for jobs, making it tough to keep things running smoothly. When companies install robots to handle those repetitive, physically demanding tasks, they actually help counteract what happens when fewer people show up for work each day. What's great about this strategy is twofold really. First, it keeps the factory moving at full speed even during lean staffing periods. Second, it frees up experienced workers from mundane duties so they can tackle problems that truly need human brains and judgment calls. Take AMI Attachments for example. They completely overhauled their shop floor with robotic arms last year. Not only did this boost product quality across the board, but their best technicians now spend most of their time doing specialized work where their years of experience actually matter instead of just pushing buttons all day long.

Advanced Quality Control Measures

Robotic systems equipped with cutting edge vision tech have become essential tools for improving product quality, especially when it comes to monitoring welding accuracy in real time. These smart systems let factory workers make quick fixes right there on the shop floor, which means fewer defective parts going to waste and better overall efficiency. Many manufacturers who've adopted these quality control upgrades see their product quality jump anywhere from 25% to 30%. Take AMI for instance they installed a state of the art robotic cell last year and saw dramatic improvements in how consistently their welds held up, plus their scrap pile got much smaller. Companies embracing these kinds of robotic solutions end up protecting their product standards while getting more done in less time, showing just how much difference good automation can make in today's manufacturing world.

Future Trends in Robotic Welding

AI and Machine Learning Integration

Bringing artificial intelligence into robotic welding is set to change things pretty dramatically in this sector. As AI continues to advance, welding robots are getting smarter programming and better at adapting on the fly, which means they can work more accurately and efficiently than ever before. These machine learning systems now analyze how good the welds look and tweak settings automatically, adjusting for different metals and tricky situations that come up during actual production runs. Industry insiders estimate that around 2025, somewhere close to half of all robotic welding systems might have some form of AI built in, making them run smoother and produce better results overall. The real advantage here isn't just about speedier production times either. Manufacturers will find themselves dealing with fewer defects and rework costs, something that becomes increasingly important as manufacturing demands get more complex day by day.

Market Growth Projections

Welding robot markets look set to grow quite a bit in coming years. Industry reports point to around 10% compound annual growth rate through the next half decade, showing how businesses are turning toward automated solutions everywhere they can. New tech developments plus stronger push for automation, especially within car manufacturing and aircraft production fields, should fuel this market expansion. Data from market research firms shows clearly that auto makers and aerospace companies stand out as major drivers behind this trend. These industries keep looking for better ways to cut down on time spent and money wasted while still getting quality results. That's why so many manufacturers are now investing in robotic welding systems not just to stay ahead of competitors but also to meet ever rising output expectations without breaking their budgets.