Understanding Intelligent Welding And Cutting in Industry 4.0

Defining Intelligent Welding And Cutting and Its Role in Modern Manufacturing

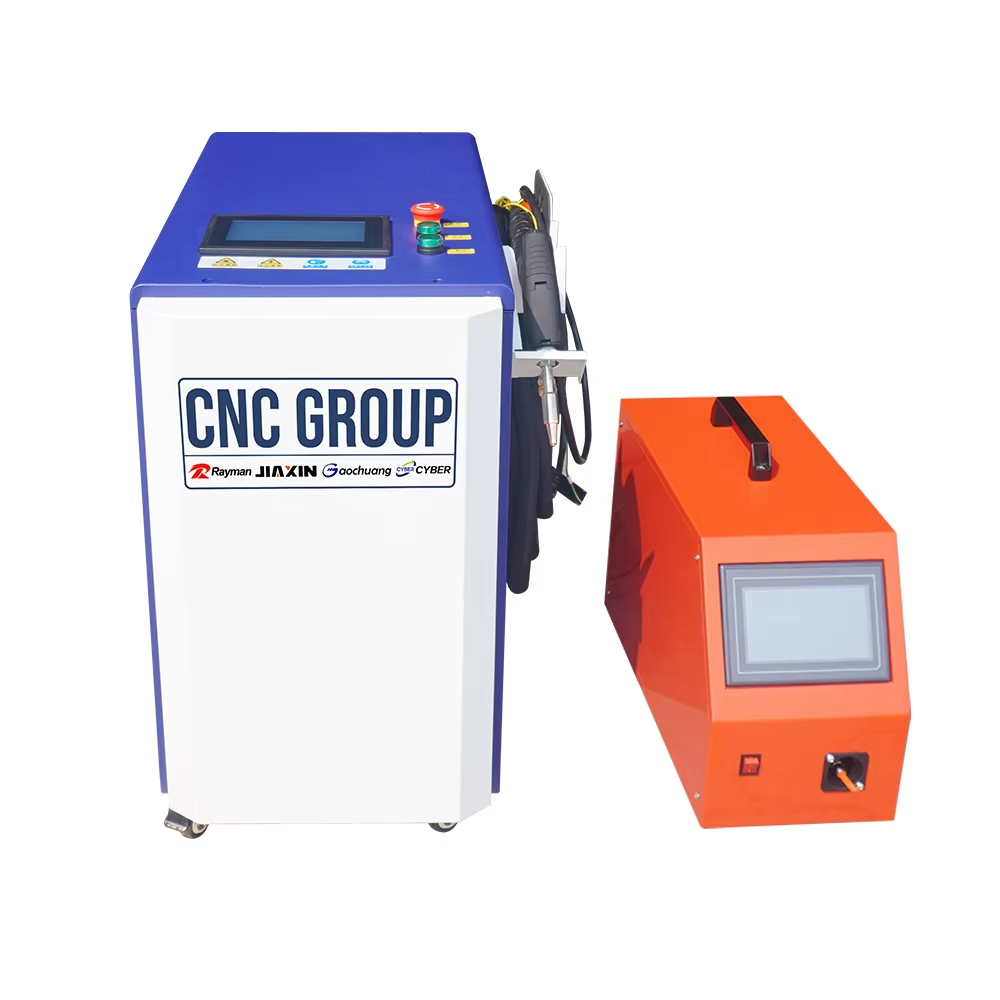

Intelligent Welding and Cutting systems represent a transformative shift in manufacturing, integrating IoT, AI, and data analytics to enable self-optimizing processes. These systems support real-time decision-making, significantly improving precision, safety, and material efficiency over traditional methods, as highlighted in industry research on smart manufacturing advantages.

The Evolution from Manual to AI-Driven Automation in Welding

Switching from traditional manual welding methods to AI driven robots represents a major leap forward for manufacturing industries everywhere. Modern welding bots can tackle intricate designs with almost pinpoint precision these days, and their smart algorithms keep getting better at figuring out the best routes and optimizing power consumption over time. What really makes this tech valuable though is how it helps predict when equipment might fail before it actually happens. This means factories spend way less time dealing with unexpected breakdowns and can maintain consistent production quality without all those frustrating interruptions that used to happen so often.

Core Technologies: Sensors, Robotics, and Real-Time Feedback Systems

Today's smart welding setups depend heavily on three main parts working together. First there are those vision sensors that track seams as they go along. Then we have robotic arms that can control force pretty well, and finally these data hubs connected to the cloud somewhere. The thermal cameras used here actually take pictures of what's happening in the melt pool area about 500 times per second. That kind of speed lets operators tweak things right away if something looks off, which helps keep the welds strong and reliable. All these pieces fit into what many call a feedback loop system. Basically, all this real time data gets analyzed constantly so improvements happen naturally over time. And because everything stays connected throughout different batches, the quality remains pretty much the same from one production run to another.

AI and Machine Learning for Precision and Defect Prevention

Smart Algorithms for Dynamic Welding Process Optimization

AI-driven algorithms dynamically adjust temperature, speed, and pressure based on real-time inputs such as material thickness, ambient conditions, and joint geometry. A 2023 ScienceDirect study found these adaptive controls improved weld quality by 32% in variable environments and reduced energy waste by up to 18% through optimized arc stability.

Adaptive Control in AI-Powered Welding Robots

Equipped with vision and force-torque sensors, modern welding robots adapt to minor misalignments and thermal distortions—critical when working with aerospace-grade alloys. Infrared monitoring allows instant compensation for heat-induced deformation, reducing rework rates by 41% in high-precision applications.

Real-Time Defect Detection Using Machine Learning Models

Deep learning models analyze multispectral imaging at 120 frames per second to detect porosity, cracks, and incomplete fusion. Convolutional neural networks (CNNs) achieve 99.2% accuracy in identifying subsurface flaws undetectable by human inspectors. When combined with automated X-ray analysis, these systems accelerate root cause diagnosis by 67% compared to manual inspection.

Real-Time Monitoring and Data Analytics for Quality Assurance

Thermal Imaging and Melt Pool Monitoring for Consistent Weld Integrity

Thermal cameras monitor melt pool behavior at over 100 frames per second, capturing temperature gradients that indicate potential defects. Deviations exceeding ±12°C trigger automatic parameter corrections, preventing issues like incomplete penetration or excess heat input. According to 2024 thermal analysis studies in heavy machinery manufacturing, this capability reduces porosity-related rework by 22%.

Optical Seam Tracking in Complex and Variable Geometries

AI-powered vision systems overcome challenges posed by curved joints and thin materials using laser-guided sensors that map surfaces with 0.05mm precision. Reinforcement learning adjusts torch angles and travel speeds in real time, reducing positional errors by 41% in automotive assembly lines, as documented in the 2024 AI-driven quality assurance report.

Predictive Quality Control Through Historical Data and Anomaly Detection

The machine learning models we've developed have been trained on weld data collected over the past five plus years, giving them an impressive ability to spot potential defects with around 95% accuracy most of the time. These systems look at all sorts of factors during the welding process including things like gas flow rates, changes in voltage levels, and how thick the materials being joined actually are. What makes this really valuable is that they can identify batches at risk well ahead of schedule – typically somewhere between 8 to 10 hours before anyone even gets around to doing the actual visual checks. The aerospace industry tested this approach back in 2023 and saw some pretty substantial savings too, cutting non-destructive testing costs by about $740,000 per year without missing any of the required quality control steps outlined in those strict ASME BPVC guidelines.

Integrating Robotic Systems and Human Expertise in Hybrid Workflows

Robotic Welding for High Consistency and Reduced Rework

Robotic welding systems maintain consistent results down to the millimeter over thousands of repetitions, which means no more unpredictable changes in how the arc behaves or how fast it moves. Studies from the latest Welding Automation Research show these machines cut down on positioning mistakes by around 87% when working on tricky joints compared to what humans can achieve. These robots shine especially well with repetitive work such as putting together car frames, but they're not just good at repetition either. Their smart software actually adjusts itself when dealing with different thicknesses of materials automatically, without needing someone to step in and fix things manually. This capability alone saves about eighteen dollars per meter in repair costs for shipbuilders who have had enough of fixing mistakes made during initial construction.

Connected Workers and Semi-Autonomous Collaboration in Smart Factories

Smart factories now have human welders working alongside robots, where they set up the machines through easy-to-use screens and keep an eye on those tricky joints that need special attention. According to a recent report on human robot teamwork from 2024, this mix of people and machines actually speeds things up quite a bit compared to just letting robots handle everything in places like airplane part production. The difference? About 25% faster cycles. And there's something else helping out too augmented reality glasses give workers instant instructions right in their field of view. This tech cuts down mistakes during setup time by around 42% when moving from one material like stainless steel to another like aluminum, which makes a big difference in getting products made correctly the first time around.

Sensor-Enabled Human-Machine Synergy in Intelligent Welding Environments

Robotic grippers equipped with tactile sensors can actually sense when a workpiece starts to deform during those tricky automotive panel welds, which then triggers adjustments to the welding torch right in the middle of the process. At the same time, these fancy inertial measurement units built into operator gloves give workers physical feedback whenever their hand movement angles go outside that safe range of plus or minus 2 degrees. What we're seeing here is two-way communication between humans and machines. The robots take care of those dangerous overhead welding jobs where safety is a big concern, while leaving the really delicate root pass work to experienced technicians who know what they're doing. This kind of举措 has shown real results too. Some studies point to productivity jumps around 31 percent when implementing this approach for upgrading oil refineries.

Scaling Intelligent Welding And Cutting Across Industries with Industry 4.0

From Standalone Cells to Networked, Cloud-Based Welding Ecosystems

Intelligent welding is evolving from isolated units into interconnected ecosystems. IoT-enabled welding cells linked via cloud platforms improve production speed by 22%, according to 2023 U.S. Department of Commerce data. This integration supports centralized control, cross-facility quality benchmarking, and automated inventory management based on real-time material usage.

Remote Monitoring and AI Automation via Cloud Platforms

Cloud-connected welding systems leverage AI to optimize parameters in real time. A 2024 automotive sector study found these platforms reduce rework costs by 40% through predictive maintenance (cutting downtime by 60%), real-time metallurgical analysis, and energy optimization models that lower power consumption by 25% per weld.

Global Adoption Trends and Strategic Implementation Roadmap

The global smart welding market is projected to grow at a 14.8% CAGR through 2030, driven by regional priorities:

| Region | Primary Adoption Driver | Implementation Barrier |

|---|---|---|

| North America | Labor cost reduction | Legacy system integration |

| Asia-Pacific | Export quality compliance | Skilled operator shortage |

| Europe | Energy efficiency mandates | Cybersecurity concerns |

Successful adopters follow a five-phase roadmap: workforce upskilling, pilot cell digitization, enterprise IoT integration, AI deployment, and continuous improvement via closed-loop analytics. The U.S. National Institute of Standards and Technology emphasizes prioritizing cybersecurity frameworks to protect proprietary welding data in cloud-based environments.

FAQ on Intelligent Welding And Cutting

What are the core technologies in intelligent welding and cutting?

Intelligent welding and cutting primarily use sensors, robotics, and real-time feedback systems to optimize the welding process.

How do AI algorithms improve welding quality?

AI algorithms adjust parameters like temperature and pressure in real-time to enhance weld stability and reduce defects, ensuring high-quality welds.

What advantages do cloud platforms offer in intelligent welding?

Cloud platforms enable remote monitoring and parameter optimization, thus improving speed, efficiency, and reducing rework costs.

Table of Contents

- Understanding Intelligent Welding And Cutting in Industry 4.0

- AI and Machine Learning for Precision and Defect Prevention

- Real-Time Monitoring and Data Analytics for Quality Assurance

- Integrating Robotic Systems and Human Expertise in Hybrid Workflows

- Scaling Intelligent Welding And Cutting Across Industries with Industry 4.0

- FAQ on Intelligent Welding And Cutting