Integration of Laser Cutting Welding in Automated Manufacturing Workflows

Understanding how laser cutting welding integrates with automated production lines

Laser cutting and welding tech works really well with automated production lines because it's a precise way to join materials without physical contact, which keeps things running smoothly even when volumes are high. What makes this technology stand out is how it can talk directly to Manufacturing Execution Systems (MES) using standard protocols. This connection lets operators monitor what's happening in real time and share data throughout the whole manufacturing process. According to recent industry reports, most factories find that their automated laser welding systems integrate with existing robotic cells at rates above 95%. That kind of compatibility means materials keep moving continuously from the cutting stage all the way to finished products on the assembly line.

Non-contact precision: How laser technology ensures consistency in high-speed automation

Laser cutting and welding work without physical contact, which means they can achieve really good precision even when moving at speeds above 100 inches per minute. The process maintains this accuracy because there's no tool wear or mechanical breakdown involved. When using focused light energy, the resulting welds have heat affected areas that measure around 0.5 mm wide. That's much narrower compared to what we see with traditional welding techniques. Since there isn't any electrode touching the material, differences caused by human operators or worn out parts just disappear. What this means is consistent weld quality throughout thousands upon thousands of production runs. Because laser systems stay so stable during operation, they're particularly well suited for jobs where tiny details matter a lot. Think about things like making medical equipment components or assembling electronic circuits where even minor inconsistencies could cause big problems down the line.

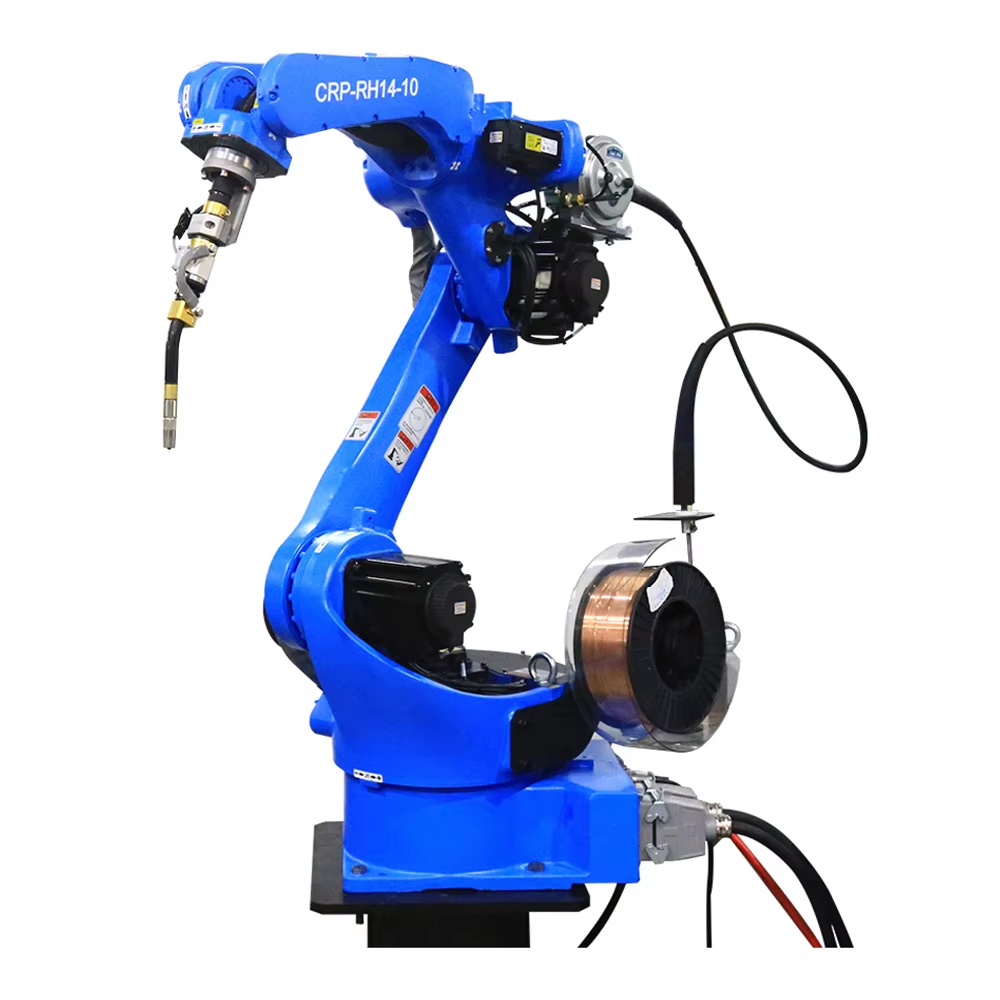

Synergy with robotic arms and conveyors for end-to-end process continuity

When laser cutting welding systems work together with six axis robotic arms and timed conveyor belts, they really boost productivity. These components get positioned with incredible precision down to fractions of a millimeter, and everything happens at just the right moment between each operation step. What this setup does is create a seamless workflow that moves parts directly from cutting through welding all the way to quality checks, so there's no need for workers to handle them manually anymore. Production shops report around 40 percent faster cycle times than when using separate machines. Plus, parts stay consistently aligned within about plus or minus 0.1 mm across the entire manufacturing process, which makes a big difference in product quality.

Industry 4.0 readiness: Connecting laser systems with digital twins and smart sensors

Laser systems today work really well with Industry 4.0 setups. They connect with digital twins and those smart sensors hooked up to the internet of things, which helps factories predict when something might go wrong and optimize operations as they happen. The process data goes into these virtual copies of actual production lines. Engineers can then try out different settings in this digital space before making changes on the factory floor. The smart sensors keep an eye on everything from how good the laser beam looks to how much gas is flowing through and what temperature things are running at. These sensors tweak the system parameters automatically so everything stays just right. What does all this mean? Well, defects get cut down by about 90% in many cases. Plus, manufacturers can track every part of the process from start to finish, knowing exactly where each component came from and what happened to it along the way.

Real-Time Monitoring and Smart Control for Reliable, High-Quality Output

AI-driven in-process monitoring for real-time defect detection in laser welding

Modern AI monitoring systems can spot welding flaws in real time by looking at data captured at the microsecond level from those fast cameras and thermal sensors we've been talking about. When these smart systems detect problems like tiny bubbles in the weld (porosity) or areas where metal didn't properly join (incomplete fusion), they flag them right away by checking how things are going against standard quality measurements. The system either sends out warnings to operators or makes adjustments on its own, stopping bad parts from moving forward through production. This saves time and money because it cuts down on having to fix mistakes later and wastes less material. For manufacturers running those super fast automated lines, this kind of instant feedback loop is absolutely essential since nobody has time to manually check every single weld.

Data feedback loops enabling adaptive control in continuous production

Laser welding systems can actually fix themselves while they're running thanks to smart data feedback mechanisms. The system has all sorts of sensors monitoring important factors like how much power the laser is putting out, where the beam is focused, and how fast it's moving across the material. All these measurements get sent back to the control system which then makes adjustments on the fly to keep everything within the right parameters for good welds. What makes this so valuable is that it handles problems automatically when materials aren't perfectly uniform or when there are changes in temperature or humidity around the workstation. This means factories can run their welding operations for hours at a time without needing someone constantly watching over them to catch issues as they happen.

Ensuring quality traceability through integrated smart control systems

Smart control systems track all the welding parameters and quality measurements during production, essentially creating a unique digital signature for every single unit made. This kind of detailed record keeping helps manufacturers meet those tough industry regulations and makes it much easier to figure out what went wrong if there are any problems down the line. What's really interesting is that all this collected information feeds into predictive maintenance algorithms. Instead of waiting until something breaks or following arbitrary schedules, technicians can now plan repairs based on real-time equipment performance data. This approach cuts down on unexpected machine stoppages and keeps product quality consistent across batches.

Enhanced Safety and Reduced Labor Dependency Through Laser Automation

Minimizing manual intervention in hazardous welding environments

Laser cutting and welding automation cuts down on how much humans get exposed to risky situations because it keeps those dangerous operations inside locked work cells. Traditional welding methods put workers right in the middle of intense heat, bad fumes, and harmful radiation, but with automated lasers, people don't need to be there at all. This separation really helps protect employees from things like arc flashes, dust particles floating around, and burns from extreme temperatures. Plus, since it's a non-contact method, there are no sparks flying everywhere, no metal bits splattering, and definitely no worries about electrodes wearing out or breaking. Looking at real world numbers, companies report around a 72% drop in accidents when they switch from manual welding to these automated systems, mainly because fewer workers are standing near machines doing dangerous stuff.

Reducing human error and improving workplace safety with automated laser systems

Laser systems that run automatically take away all those problems that come from workers getting tired, distracted, or just not doing things exactly the same way every time. These machines can do welds again and again with really tiny differences measured in microns. When it comes to safety, this kind of precision stops major issues like welds that don't go all the way through or joints that aren't properly prepared, which might actually weaken the whole structure. The system also has these real time monitors watching everything closely. If something goes off track and crosses into unsafe territory, the whole operation just stops automatically. That lets us catch problems before they become accidents. Since there's no need for so many people working directly on the shop floor anymore, workers aren't exposed to as many dangerous situations during normal operations. Overall, this makes the whole manufacturing process much safer from start to finish.

Scaling Laser Cutting Welding from Prototype to Mass Production

Maintaining precision and weld integrity when scaling laser processes

Moving laser cutting welding operations from prototype stages to full scale manufacturing requires tight control of several key factors including beam settings and workshop environment. The advantage of minimal heat affected zones helps reduce warping in components, but getting repeatable welds means maintaining stable energy levels throughout the process. Modern production facilities rely on sophisticated monitoring equipment to keep tabs on laser power fluctuations, lens alignment, and how well protective gases are working during each cycle. These systems make sure every single item comes out looking and performing exactly like the last one, no matter if we're talking about just a handful of test pieces or running through thousands for an order.

Overcoming challenges in beam stability and process consistency at scale

When manufacturers move their operations from single station setups to multi head production lines, they run into some serious beam delivery issues. Fiber lasers definitely have better beam quality when transmitting over longer distances, though this comes at a cost. All those stations need spot on calibration if we want consistent results across the board. The good news is automated calibration systems can cut down parameter drift by around three quarters compared to what happens with manual adjustments. This makes a world of difference for maintaining product quality while also slashing the time it takes to get everything set up properly in big manufacturing facilities.

Automation’s role in boosting productivity and lowering operational costs

When automation gets integrated into laser welding processes, it turns what was once a slow method into something that can scale up production dramatically. Modern robotic systems working alongside laser cutting equipment allow factories to run non-stop operations even when nobody's watching, which cuts down on the need for workers. The result? Factories report anywhere from triple to quadruple the output compared to traditional manual techniques. What's really interesting is how this approach maintains product quality despite requiring so much less hands-on work. According to various industry studies, companies dealing with large order volumes typically see around a third drop in operating expenses after implementing these automated solutions.

Evaluating ROI and Selecting the Right Partner for Laser System Integration

Conducting ROI analysis: Laser welding speed and efficiency vs. traditional methods

When looking at return on investment for laser cutting and welding, it makes sense to pit these technologies against older methods in several different ways. According to the latest Manufacturing Efficiency Report from 2023, laser systems generally run about three to five times quicker than conventional approaches, all while using roughly half as much power. There's another big plus too - no need for those expensive electrodes or filler materials that eat into budgets. Plus, when things get cut with such accuracy, there's simply less waste material lying around and fewer mistakes needing fixing later on. What really matters when doing this kind of comparison?

- Throughput improvements: Measure increased output per shift

- Operational savings: Account for lower energy, maintenance, and consumable expenses

- Quality gains: Include reductions in defect rates and material waste

- Labor optimization: Factor in reduced staffing needs and training costs

Most manufacturers achieve payback within 18–24 months, followed by annual savings of 30–40% compared to conventional welding.

Choosing an automation partner with MES compatibility and integration expertise

Success in laser system integration depends heavily on selecting a partner with proven experience in MES connectivity and Industry 4.0 deployment. The ideal provider offers end-to-end support—from feasibility studies to full implementation—ensuring seamless integration with existing equipment and software. Critical capabilities include:

- System compatibility validation: Confirming interoperability with current platforms

- Scalability planning: Designing future-ready solutions that grow with demand

- Training programs: Delivering customized training for operators and maintenance teams

- Ongoing support: Providing technical assistance and performance optimization

Data shows manufacturers who partner with specialized integrators achieve 40% faster deployment and 25% higher overall equipment effectiveness (OEE) than those pursuing in-house implementations.

Frequently Asked Questions

What are the benefits of integrating laser cutting welding in automated production lines?

Integrating laser cutting welding brings high precision and efficiency, eliminates tool wear, and ensures consistent weld quality, boosting productivity on automated lines.

How does AI enhance laser welding processes?

AI improves laser welding by real-time defect detection, adaptive control, and quality traceability, all of which contribute to reliable and high-quality production.

Why is laser welding safer than traditional methods?

Laser welding is safer due to its non-contact nature, reducing worker exposure to harmful conditions and minimizing human error, thus improving safety and efficiency.

What factors are crucial for scaling laser welding from prototype to mass production?

Maintaining precision in laser parameters, ensuring beam stability, and leveraging automation for enhanced productivity are vital factors when scaling laser processes from prototype to mass production.

How can companies evaluate the ROI of laser cutting welding?

Companies can evaluate ROI by comparing throughput improvements, operational savings, quality gains, and reduced labor needs between laser and traditional welding methods.

Table of Contents

-

Integration of Laser Cutting Welding in Automated Manufacturing Workflows

- Understanding how laser cutting welding integrates with automated production lines

- Non-contact precision: How laser technology ensures consistency in high-speed automation

- Synergy with robotic arms and conveyors for end-to-end process continuity

- Industry 4.0 readiness: Connecting laser systems with digital twins and smart sensors

- Real-Time Monitoring and Smart Control for Reliable, High-Quality Output

- Enhanced Safety and Reduced Labor Dependency Through Laser Automation

- Scaling Laser Cutting Welding from Prototype to Mass Production

- Evaluating ROI and Selecting the Right Partner for Laser System Integration

-

Frequently Asked Questions

- What are the benefits of integrating laser cutting welding in automated production lines?

- How does AI enhance laser welding processes?

- Why is laser welding safer than traditional methods?

- What factors are crucial for scaling laser welding from prototype to mass production?

- How can companies evaluate the ROI of laser cutting welding?