How Robot Dogs Enhance Operational Visibility and Inspection Accuracy

Spot Robot for Factory Inspections: Real-Time Monitoring and Data Capture

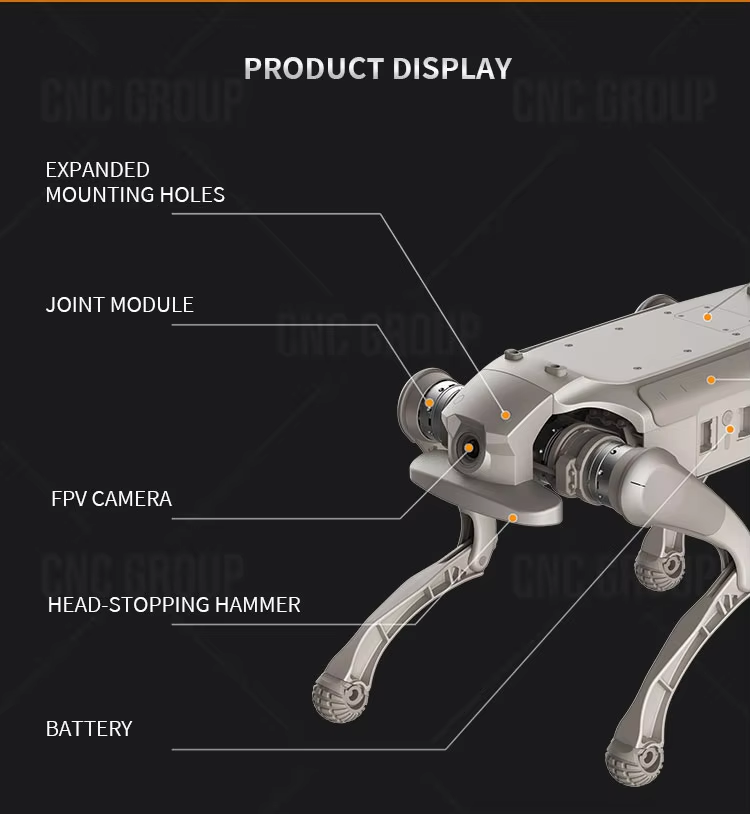

Facility patrol robot dogs come packed with all sorts of sensors that let them capture thermal images, detect vibrations, and measure air quality as they move around. These four-legged inspectors cut down on manual checks by about two thirds, and they spot problems roughly three times faster than what humans can manage during regular inspections. What sets them apart from just hanging cameras on walls is those flexible legs and full circle movement capabilities. They can actually get into tight spots most traditional systems miss entirely, like crawling underneath heavy machinery or squeezing through narrow ventilation ducts where no one wants to stick their head.

AI-Powered Inspection Systems in Manufacturing: Detecting Anomalies With Precision

Industrial machine vision systems now spot those tiny cracks in welds down to about 0.2mm and catch components that aren't lined up properly with nearly 99.4% accuracy according to testing. Researchers at UT Permian Basin did a study last year looking into this stuff, and what they found was pretty impressive actually. The AI systems cut down on false alarms by around three quarters when compared to older rule based approaches. And let's face it, fewer false alarms means less time wasting everyone when the production line stops for no good reason. Manufacturers report saving roughly 37 man hours each year just on one assembly line alone after implementing these smarter inspection technologies.

Ultrasound and Sensor Fusion: Early Failure Detection Using Mobile Robotic Platforms

By integrating ultrasonic thickness gauges with LiDAR mapping, robot dogs detect pipeline corrosion 6-8 weeks earlier than manual inspections. Sensor fusion algorithms cross-reference sound wave reflections with 3D spatial data to pinpoint wall thickness variations below 0.5mm-critical for preventing chemical leaks in petrochemical plants.

Automated Data Collection and Analysis: Turning Insights Into Action

The robotic inspection systems we've implemented now create those repair lists automatically, cutting down our reporting time dramatically—from about 14 hours down to just 22 minutes each shift. Looking at actual numbers from one of our smart factories, places that use these automated systems fix around 89 out of every 100 problems they spot within two days. Compare that to older facilities where someone has to check everything by hand, and only about 3 in 10 issues get fixed that fast. And this matters because when small problems aren't caught early enough, they turn into big breakdowns. The Ponemon Institute put some real money figures on this back in 2023 showing these kinds of failures typically run companies about $740,000 each time they happen.

Enabling Predictive Maintenance and Continuous Autonomous Monitoring

From Reactive to Predictive Maintenance: The Role of Robot Dogs in Asset Health Tracking

The world of industrial maintenance is moving away from fixing things after they break down toward smarter approaches based on real-time data, and four-legged robots are becoming really important in this change. These mechanical dogs come packed with thermal imaging gear and vibration detectors that let them gather information about how machines are doing in places humans can't easily access. According to a report published on LinkedIn last year, companies that started using these robotic inspectors saw their unexpected breakdowns cut nearly in half while also getting almost 20% more life out of their expensive equipment. Manufacturing plants and power stations especially benefit from this technology since it helps prevent costly shutdowns and extends the useful life of critical machinery.

Persistent Patrol Robots for 24/7 Autonomous Safety and Maintenance Checks

Modern robot dogs operate autonomously for over 200 hours between charges, executing predefined routes with millimeter-level repeatability. Their persistent presence enables:

- Continuous baseline establishment: AI detects micron-level deviations in motor vibrations or bearing temperatures

- Hazard mitigation: Gas sensors identify toxic leaks four times faster than stationary detectors (OSHA 2023 safety audit data)

Orbit Platform and Analytics: Generating Actionable Maintenance Insights

Advanced analytics transform raw sensor data into prioritized work orders by correlating performance trends with maintenance histories-revealing failure patterns often missed by humans. For example, one manufacturer discovered a 92% correlation between specific motor temperature fluctuations and impending bearing failures through robotic inspection data.

Case Study: Robot Dog Deployment in a Tier-1 Automotive Manufacturing Plant

A major automotive OEM implemented robot dogs for powertrain assembly line monitoring, achieving:

- 83% faster defect detection compared to manual checks

- 37% reduction in monthly maintenance labor costs

- Zero safety incidents in high-voltage battery testing areas post-deployment

By feeding real-time data into predictive maintenance algorithms, the plant now schedules 89% of maintenance activities proactively-a critical advantage in just-in-time manufacturing.

Improving Worker Safety and Reducing Human Exposure to Hazards

Enhancing Safety in Factory Environments Through Robotic Presence

In places where danger lurks, robot dogs now take over patrols around chemical storage areas and those tight machinery corridors. These mechanical companions spot problems like overheating gear or toxic leaks about 38 percent quicker than when humans do the checking manually, according to International Labour Organization data from 2025. The fact that they can keep watch all day long means workers don't have to enter those cramped, risky spaces so often. Looking at numbers from the Workplace Hazard Analysis report for 2025, this alone cuts down on fatal incidents by roughly a quarter among industries where confined space entry remains a major concern.

Reducing On-Site Personnel During High-Risk Operations via Robot Dog Deployment

In environments like automotive paint shops and semiconductor cleanrooms, robot dogs handle hazardous tasks without exposing workers. A single deployment can reduce personnel hours in radiation-controlled areas by 71% while maintaining inspection frequency. Advanced collision-avoidance systems allow safe navigation through active forklift routes, eliminating 92% of vehicle-pedestrian near-misses in pilot programs.

Controversy Analysis: Balancing AI Diagnostic Accuracy With False Positive Rates

While robot dogs achieve 89% defect detection accuracy in controlled trials, field deployments show a 12% false positive rate for gas leak alerts. Over-alert fatigue remains a concern, with maintenance teams ignoring 15% of legitimate warnings after repeated false triggers, according to manufacturing behavioral studies.

Industry Paradox: High ROI Potential vs. Initial Resistance to Robotic Adoption

Early adopters report a 34% reduction in safety incident costs within 12 months, yet 63% of factory managers cite workforce skepticism as the primary adoption barrier. This resistance persists despite data showing a 19-month average payback period for robotic safety systems in heavy industrial settings.

Integrating Robot Dogs with Digital Twins and Smart Factory Infrastructure

Reality capture and 3D modeling using robot-mounted sensors

Factory floor robot dogs with LiDAR and photogrammetry tech can generate super accurate 3D maps down to the millimeter as they do their regular rounds. These robots give manufacturers a whole new way to spot structural problems in tight spots that would take way longer to find manually. According to a recent report from Matterport in their 2025 Industrial IoT study, this kind of spatial awareness cuts inspection time by about 47%. And these mobile units don't just map out static structures either. They pick up on temperature changes and vibrations across the facility too, which helps engineers figure out how to rearrange equipment for better workflow efficiency.

Digital twin synchronization with real-time data from robot dog patrols

Top manufacturers are hitting around 92 percent accuracy with their digital twins when they combine sensor data from robots with virtual factory models. According to research published in 2024 on smart manufacturing practices, companies saw commissioning times drop by about 38% for brand new production lines. This happened because engineers could run virtual tests first to check if robotic arms would crash into things or if automated guided vehicles might get stuck somewhere. With all that real-time data flowing constantly, plant managers can now spot potential workflow problems long before anyone has to make actual changes on the factory floor. Some factories even report catching issues weeks ahead of schedule thanks to these predictive simulations.

Strategy: Leveraging spatial data for layout optimization and workflow redesign

Plant managers use heatmap analytics from robot patrols to reconfigure high-traffic zones, improving worker-robot collaboration safety. Machine learning algorithms process 12+ data streams-including temperature, airflow, and vibration-to recommend equipment repositioning that increases production line throughput by 14-22%.

Synergy between industrial automation and robotics in smart factories

Robot dogs working alongside PLC-controlled machines are transforming factory floors into smarter production environments. These four-legged assistants provide valuable information from floor level that standard SCADA systems often miss, which helps managers tweak AGV paths when things get busy on the shop floor. The results speak for themselves in major automotive factories where companies report seeing their investment pay off within 8 to 12 months thanks to fewer production stoppages and lower electricity bills across the plant.

FAQ

What are the main benefits of using robot dogs in industrial inspections?

The main benefits include enhanced operational visibility, faster problem detection, reduced manual inspections, improved safety, and significant cost savings.

How do robot dogs detect issues that humans might miss?

Robot dogs use sensors for thermal imaging, vibration detection, and air quality measurement. They access tight spaces where humans can't easily reach and combine various data for accurate issue detection.

What is the impact of robot dogs on predictive maintenance?

Robot dogs provide real-time data that help initiate predictive maintenance, leading to reduced unexpected breakdowns and extended equipment life.

How do robot dogs contribute to worker safety?

By handling hazardous inspections and monitoring, robot dogs reduce human exposure to dangerous environments, thereby improving workplace safety.

Are there any drawbacks to using robot dogs?

While robot dogs have many advantages, they may have false-positive rates, and there may be workforce skepticism regarding their adoption.

Table of Contents

-

How Robot Dogs Enhance Operational Visibility and Inspection Accuracy

- Spot Robot for Factory Inspections: Real-Time Monitoring and Data Capture

- AI-Powered Inspection Systems in Manufacturing: Detecting Anomalies With Precision

- Ultrasound and Sensor Fusion: Early Failure Detection Using Mobile Robotic Platforms

- Automated Data Collection and Analysis: Turning Insights Into Action

-

Enabling Predictive Maintenance and Continuous Autonomous Monitoring

- From Reactive to Predictive Maintenance: The Role of Robot Dogs in Asset Health Tracking

- Persistent Patrol Robots for 24/7 Autonomous Safety and Maintenance Checks

- Orbit Platform and Analytics: Generating Actionable Maintenance Insights

- Case Study: Robot Dog Deployment in a Tier-1 Automotive Manufacturing Plant

-

Improving Worker Safety and Reducing Human Exposure to Hazards

- Enhancing Safety in Factory Environments Through Robotic Presence

- Reducing On-Site Personnel During High-Risk Operations via Robot Dog Deployment

- Controversy Analysis: Balancing AI Diagnostic Accuracy With False Positive Rates

- Industry Paradox: High ROI Potential vs. Initial Resistance to Robotic Adoption

- Integrating Robot Dogs with Digital Twins and Smart Factory Infrastructure