What Is a Welding Robot and How It Works

Understanding the Basic Function of a Welding Robot

Welding robots are essentially machines that can be programmed to handle arc welding jobs automatically. These systems typically feature a robotic arm connected to a power supply and welding torch setup that follows specific paths during operation. The system adjusts things like voltage levels, current strength, and how fast the torch moves along the workpiece. Modern units come equipped with built-in sensors that pick up information about where joints are located and what thickness materials are being worked on. This allows the robot to make adjustments on the fly so welds end up exactly where they need to be. Quality improvements from using such automation are pretty impressive too. According to recent research published in 2023 by Ponemon Institute, robotic welding systems cut down on defective welds by around 80 percent when compared to traditional hand welding methods.

The Role of Automation in Modern Welding Processes

Automated welding tackles some major problems that plague traditional methods these days. Think about human mistakes, inconsistent weld quality, and those dangerous fumes workers have to deal with daily. Robotic welders just keep going round the clock without getting tired or distracted. They produce consistent welds even when dealing with tricky shapes and angles that would challenge any human operator. Some newer systems come equipped with smart features too. Adaptive path planning technology lets robots compensate when parts aren't perfectly aligned something that happens all the time on factory floors. The numbers back this up as well. Plants that switched to robotic welding systems saw their downtime drop by almost half according to industry reports from last year.

Rise of Robotic Welding in Small and Medium Enterprises

Once limited to large manufacturers, robotic welding is now accessible to SMEs thanks to cost-effective systems starting at $50,000 and user-friendly programming interfaces. A 2025 industry survey found that 40% of small fabricators use robotic welding for at least one process, driven by:

- Faster setup times (50% reduction compared to legacy systems)

- Lower skill requirements (operators train in days, not months)

- Scalable workflows (systems adapt to low- or high-mix production)

These advantages allow SMEs to improve quality control and compete more effectively with larger manufacturers.

Types of Welding Robots and Their Industrial Applications

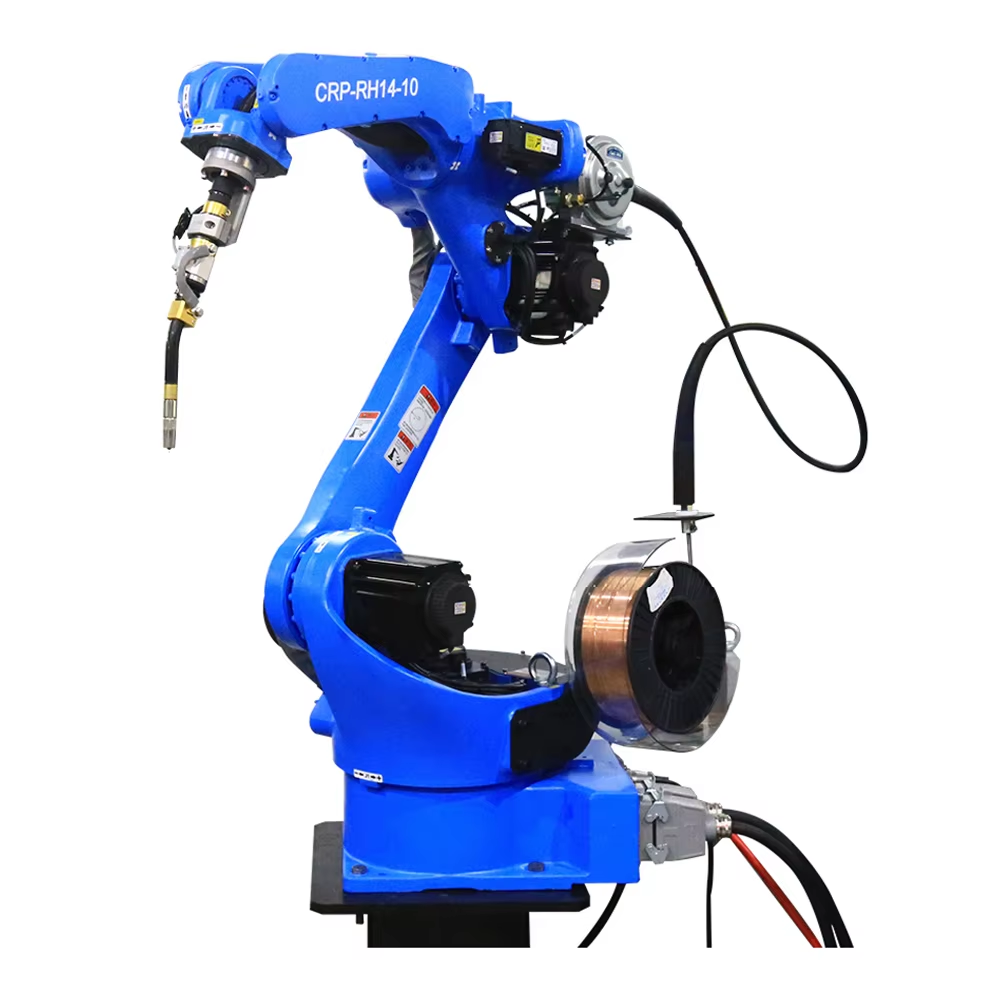

Articulated Robotic Arms for Flexible Welding Tasks

Robotic arms that articulate across six axes move pretty much like human arms do, which makes them ideal for complicated welding jobs where precision matters most. These machines have become standard equipment on assembly lines, especially when it comes to putting together car underbodies and exhaust systems in tight spots that would be impossible for humans to reach comfortably. What's really impressive is how versatile they are. One machine can handle all sorts of welds from those tricky overlapping seams to perfect circular joints, maintaining accuracy within about 0.1 mm each time. Manufacturers report seeing around a third less rework needed after switching from manual welding to these robotic solutions, which translates into real savings over time.

Cartesian and SCARA Robots in High-Precision Environments

Both Cartesian (those linear axis types) and SCARA robots (Selective Compliance Articulated Robot Arms if we're being technical) offer remarkable precision when it comes to straight line work or fast welding jobs. The SCARA models really shine in electronic assembly tasks, their quick up and down movements making them great for producing clean TIG welds on those tricky heat sink components. For bigger projects like aircraft construction, Cartesian systems work wonders since they move along three axes X, Y and Z. These machines handle massive structural welding with impressive results, hitting nearly 99.8% accuracy even on long 10 meter I-beams which is pretty amazing considering the scale involved.

Collaborative Robots (Cobots) vs. Fully Automated Welding Systems

Cobots let workers and machines work together safely without those big safety cages, which is why many small to medium businesses are getting interested. Traditional automation setups need around quarter of a million dollars worth of equipment, but collaborative robots like the UR10e can be up and running within just eight hours or so. They also handle smaller production runs much better than regular machines. According to research from last year, companies using cobot welders saved about two thirds on their setup costs when producing fewer than 500 items at a time. However, if a business needs to produce over 50 thousand welds each year, going with traditional systems still makes more financial sense despite the higher initial investment.

Case Study: Cobot Integration in a Custom Fabrication Shop

A sheet metal shop in Ohio swapped out their old manual MIG welding setup for two collaborative robot stations that now handle around 80 percent of all stainless steel exhaust work they get. The new vision guided systems actually account for those tricky +/- 3mm part variations that used to drive everyone crazy, which brought down their scrap rate dramatically from 12% down to just 2.1% over half a year. What's really interesting is what happened to the workers too. Instead of losing jobs, most of them moved into programming tasks and quality checks. Production tripled while overtime completely disappeared from the schedule. And even though it cost about $75,000 upfront, the company got every penny back in just 14 months according to their calculations.

Core Components of a Welding Robot System

Robotic Arm, Power Source, Torch, and Control Interface Explained

Every welding robot relies on four synchronized components:

- Robotic arms, typically 6-axis, provide 3D maneuverability and achieve ±0.05 mm repeatability in arc welding.

- The power source regulates voltage and amperage, with modern pulsed MIG/MAG systems enabling 40% faster weld speeds (Ponemon 2023).

- Welding torches feature air or water cooling and consumables rated for 500+ hours in high-spatter environments.

- Control interfaces include teach pendants and PLC integration, allowing storage of over 1,000 weld parameter profiles for multi-material jobs.

Integration of Wire Feeders and Shielding Gas Systems

Precision wire feeders maintain 0.1 m/min accuracy even at 15-meter cable lengths, reducing porosity defects by 32% in aluminum welding. IoT-enabled regulators dynamically adjust shielding gas flow to maintain optimal 20–25 CFH rates, essential for stainless steel and nickel alloy applications.

How Components Synchronize for Consistent Weld Quality

Advanced robots use real-time feedback loops: vision sensors detect joint misalignments as small as 0.3 mm and trigger path corrections within 50 ms. Torch angle, wire feed speed, and arc length are continuously optimized via 200 Hz sampling, resulting in 99.4% first-pass yield rates in demanding applications like automotive underbody welding.

Welding Processes Compatible with Robotic Automation

MIG Welding Automation: Speed and Efficiency Gains

MIG welding robots have become a staple in mass production settings thanks to their ability to run nonstop with quick wire feeding. These machines cut down on waiting time significantly when compared to what human welders can manage, which explains why so many car factories and appliance makers rely on them. The robots follow programmed routes that keep the weld beads looking uniform across every product. Their smart voltage adjustments also help cut back on those annoying splatters that waste material and require cleanup. For companies where speed matters most, these features make all the difference in keeping production lines moving efficiently day after day.

TIG Welding with Robots: Precision for Critical Joints

TIG welding robots can achieve incredibly fine precision down to the micron level, making them ideal for critical applications in both aerospace manufacturing and medical device production. These machines have advanced features that allow exact control over the torch angle while adjusting current levels in real time, resulting in consistently good welds even when working with delicate materials such as thin gauge stainless steel or aluminum sheets. An actual case study from an aerospace company showed dramatic improvements too - their rework rates dropped by almost 92 percent once they started using automated TIG systems specifically for assembling aircraft fuel lines where quality cannot be compromised.

Flux-Core and Spot Welding in Robotic Cells

- Flux-core robots handle thick structural steel with minimal porosity, using self-shielding wires that perform well in windy outdoor conditions

- Spot welding arms complete over 600 joins per hour in automotive body shops, employing servo-driven electrodes for uniform pressure and consistent weld strength

Expanding Robotic Adaptability Across Welding Types

Emerging technologies such as laser-hybrid welding and AI-driven seam tracking now allow robots to weld copper alloys and mixed-material joints. A 2023 study found modern systems support 14% more welding variants than pre-2020 models, narrowing the gap between mass production and custom fabrication.

Benefits, Costs, and ROI of Implementing a Welding Robot

Increased Productivity Through 24/7 Operation

Welding robots operate continuously with 85–95% uptime, free from fatigue or shift limitations. This enables manufacturers to complete large batches two to three times faster than manual teams, especially in high-volume MIG and spot welding applications.

Enhanced Weld Quality and Consistency

Robotic systems achieve ±0.04 mm repeatability, reducing defects like porosity and undercut by 63% compared to manual methods (American Welding Society 2024). Seam tracking sensors automatically adjust arc parameters mid-weld, maintaining high quality even on warped or inconsistently fitted materials—crucial for aerospace and automotive contractors.

Improved Workplace Safety and Reduced Operator Exposure

Robots handle hazardous tasks such as overhead welding and fume-intensive operations, reducing workplace injuries by 41% in metal fabrication. This shift allows skilled workers to focus on supervision, programming, and complex joint preparation—improving both safety and job satisfaction.

Balancing High Initial Cost with Long-Term Savings

Entry-level cobot welding cells start around $50,000, while industrial systems can exceed $200,000. However, most manufacturers recover costs within 18 to 30 months. For example, a Midwest fabricator reduced rework expenses by $18,000 per month after implementing robotic welding, achieving ROI on their $145,000 system in just eight months.

Calculating Return on Investment for Small and Medium Shops

Key ROI factors include:

- Throughput gains: 24/7 operation increases output without added labor

- Material efficiency: 12–15% reduction in wire waste and spatter

- Labor reallocation: One operator can manage multiple robotic cells instead of performing repetitive welding

The global robotic welding market is projected to grow at a 10% CAGR through 2032, reflecting increasing confidence in these economic and operational benefits across small and medium enterprises.

FAQs about Welding Robots

What are the main benefits of using welding robots?

Welding robots offer increased productivity, improved weld quality, better workplace safety, and significant cost savings over the long term. They are capable of operating 24/7, providing consistent and precise welds, while reducing hazardous task exposure for workers.

What types of welding robots are available for industrial applications?

There are several types of welding robots, including articulated robotic arms, Cartesian and SCARA robots, and collaborative robots (cobots). Each type serves different purposes, providing flexibility, precision, and adaptability for various welding tasks.

Are welding robots suitable for small and medium enterprises?

Yes, welding robots are increasingly accessible to small and medium enterprises (SMEs) with cost-effective systems and user-friendly programming interfaces. Many SMEs have started using robotic welding to improve quality control and compete with larger manufacturers.

How does robotic welding improve workplace safety?

Robotic welding reduces workplace injuries by handling hazardous tasks such as overhead welding and fume-intensive operations. This shift allows workers to focus on supervision and programming, enhancing job safety and satisfaction.